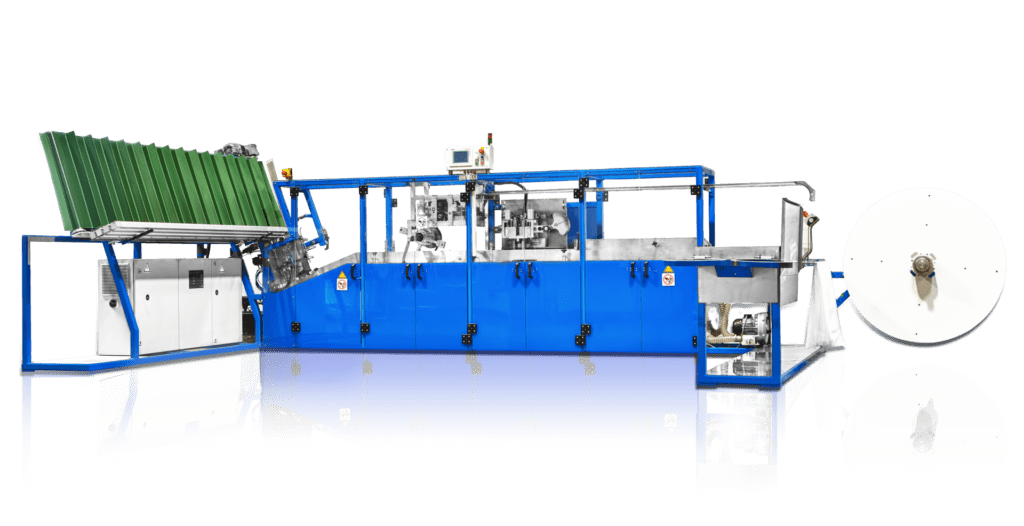

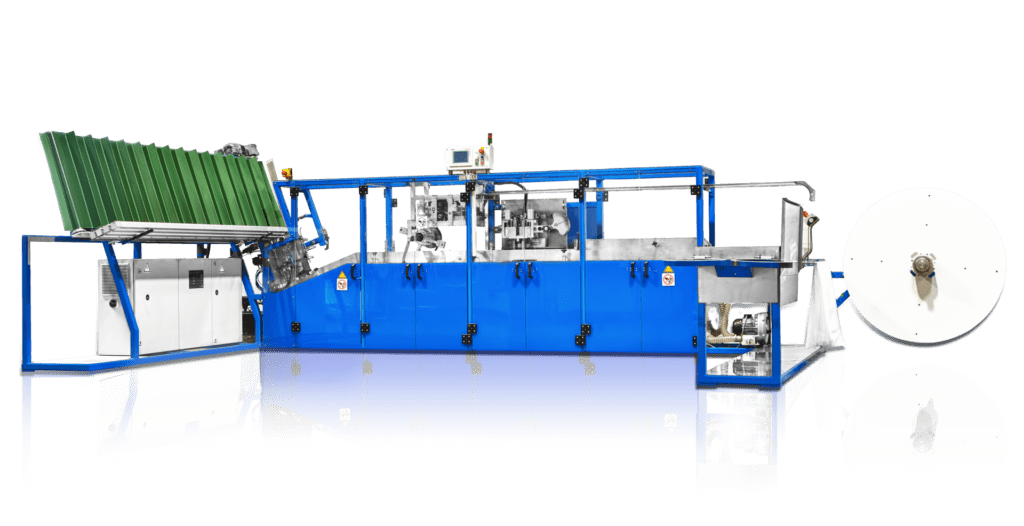

USM 250

Tray padding machine

USM 250

Less energy consumption - more performance: Our soak pads insertion machine

The USM 250 tray padding machine is ideally suited for efficient and reliable insertion of absorbent pads into trays for meat, fish and fruit packaging.

Our padding lines or soaker pads inserters process all common tray formats made of various plastic materials, such as PP, PET, or EPS. Special formats such as special shells with double chambers are also possible.

As a machine type of the new generation, the tray padding machine type USM 250 impresses with its 2-point ultrasonic welding technology. Die LAD Maschinen entsprechen den höchsten Hygienestandards und Gesundheitsstandards, da sie ganz ohne Heißleim auskommen.

The USM 250 is ergonomically designed and proves to be extremely user-friendly, allowing it to be easily operated by a single worker.

Their output is up to 160 trays/minute. With the highest precision, the USM 250 inserts the suction inserts into the plastic trays and fixes them by means of ultrasonic welding at two points on the tray base. This guarantees a tight fit of the soaker pads and thus a safe transport of the fresh product from the production hall to the end consumer.

Hot glue technology can be integrated into the machine for special applications.

Using various options, a high level of quality control is made possible.

Faster, safer, more flexible - USM 250 tray machine

Options

The double tray detector (2) checks whether the trays have been correctly separated from the denester (1). If the detector detects that two trays are still stacked inside each other, they are conveyed out of the machine by the ejection unit.

The camera control system detects whether there is an absorbent pad in the tray and whether it is in the correct position.

If the absorbent pad is missing or incorrectly positioned, the trays are automatically sorted out.

The leak test of the trays also detects microscopic holes that can form in the trays during ultrasonic welding of the absorbent pads. Affected trays are automatically sorted out by the machine accordingly.